Introduction

Ford Powerstroke diesel engines are known for their power, reliability, and impressive towing capabilities. However, even the most robust engines can experience certain issues, and one problem that has plagued Powerstroke owners is the failure of the CP4 pump.

The dreaded CP4 pump failure can be very sobering for your pocket as costs can top the $10,000 range. The high cost is a result of metal shavings being released into the fuel system, wreaking havoc and can end in catastrophic failure.

As the CP4 fuel pump deteriorates, it releases metal shavings and contaminants that end up polluting components in the fuel system, such as the fuel rails, high-pressure lines, injectors, overflow valve, and return lines. Simply flushing the fuel system won't be enough because some of these harmful particles can remain. To fully resolve the issue, it's necessary to replace all the affected components in the fuel system.

In this article, we will delve into the details of the CP4 pump, explore the reasons behind its failure, and discuss the symptoms associated with this issue.

Understanding the CP4 Pump

The CP4 pump, short for Common Rail Pump 4, is a high-pressure fuel pump used in Ford Powerstroke 6.7L diesel engines. It plays a crucial role in supplying pressurized fuel to the fuel injectors, allowing for efficient combustion and power generation. The CP4 pump is designed to handle the demanding requirements of modern diesel engines, but unfortunately, it is prone to failure under certain conditions.

Reasons for CP4 Pump Failure

Several factors contribute to the failure of the CP4 pump. One primary cause is the pump's susceptibility to internal wear and damage when exposed to low-lubricity fuels.

Another problem can be the formation of air bubbles inside the housing if the pump has trouble supplying adequate fuel. The presence of air in the pump leads to direct metal-to-metal contact or even permits the rotation of a lifter. Since there is no mechanical lock or keyway to maintain its proper orientation, a lifter can rotate by 90 degrees. If a lifter has turned sideways it will begin to cut into the main shaft, rather than ride on it smoothly.

All these potential issues will result in accelerated wear and metal particles in your fuel system.

Moreover, the CP4 pump relies on the diesel fuel for both lubrication and cooling, making it particularly vulnerable to fuel contaminants.

Symptoms of a Failing CP4 Pump

Img source: Fontenot’s Diesel

The symptoms of a failing CP4 pump can be varied, from trouble starting all the way to complete engine failure. Here are some common signs that indicate potential issues with the CP4 pump in Ford Powerstroke vehicles:

Hard Starting: One of the initial signs of a failing CP4 pump is difficulty starting the engine. The pump may struggle to deliver an adequate amount of fuel to the injectors, causing extended cranking times or even failed starts.

Loss of Power: As the CP4 pump's performance deteriorates, the engine may experience a noticeable loss of power. This can result in reduced acceleration, sluggishness, or overall poor performance.

Engine Misfires: A failing CP4 pump can cause fuel delivery inconsistencies, leading to engine misfires. This symptom is often accompanied by rough idling, vibration, or unusual engine sounds.

Illuminated Check Engine Light: A malfunctioning CP4 pump can trigger the vehicle's on board diagnostics system, causing the check engine light to illuminate. This is typically accompanied by the storage of relevant error codes that can help pinpoint the problem.

Complete Engine Failure: In severe cases, a failed CP4 pump can result in complete engine shutdown. If left unaddressed, this can cause significant damage to the fuel system and other engine components.

Preventive Measures

While CP4 pump failures can be very costly and inconvenient, there are few options that Powerstroke owners can take to prevent this problem from ever occurring, or to mitigate the risks and extend the lifespan of their pumps.

1. Replace the problematic CP4 with a failure-proof DCR pump

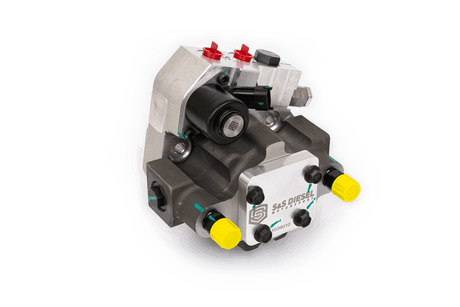

Our top pick, and the only 100% failure proof solution is to replace the problematic pump with S&S Diesel’s Ford 6.7 CP4 to DCR Fuel Pump Conversion Kit. Though not the cheapest alternative, this will guarantee you peace of mind knowing there is no risk of a 10K-12K bill surprising you in the future.

With the looks and performance of OEM parts; this DCR Pump Conversion by S&S is a game changer; low noise, fast response time, & no tuning or calibration required. this conversion will save you potentially thousands in repairs if your CP4 happens to fail.

S&S Diesel

2011-2025 Powerstroke CP4 to DCR Fuel Injection Pump Conversion Kit (6.7F-DCR-1)

2. Install a CP4 Bypass “Disaster Prevention Kit”

Though this kit won’t prevent your CP4 from failing, it will safeguard your fuel injectors, rails, lines, and tank from CP4 debris. Though initially a cheaper option than the CP4 to DCR conversion listed above, if your CP4 does fail, this could prove to be run a similar cost, or risk being costlier based on the cost of a replacement OEM CP4.

S&S Diesel Motorsport, the creator of the original Disaster Prevention Kit for the 6.7 Power Stroke, is at it again with a much-improved second-generation kit. Since its debut in 2016, the original S&S 6.7L Power Stroke CP4 Bypass Kit (Disaster Prevention Kit) has safeguarded thousands of injectors from CP4 debris.

S&S Diesel

2011-2025 Powerstroke Gen2.1 CP4 Bypass Kit w/ Return Filter Assembly (CP4-6.7F-BP-G2.1)

3. Install an Exergy Fuel System Saver

Like the S&S disaster prevention kit, the Exergy Fuel System Saver won’t stop your CP4 from failing, but it will do a significantly better job than the OEM filter of keeping your injectors free of metal contaminants.

The System Saver Inlet Valve was designed a bit differently than the OEM valve, Exergy made improvements to the screen that is upstream of the valve inlet. The OEM screen is a single 80-Micron layer and is extremely flimsy, the OEM screen is prone to tearing and introducing massive amounts of debris from the failed pump into the injectors. The System Saver is rated at 25-Microns and is double wrapped in two layers and does a significantly better job of keeping debris from entering the rest of the fuel system.

Exergy

2011-2019 Duramax & Powerstroke Fuel System Saver (E05 10505)

4. Running OEM Motocraft Filters

Another recommendation for maintaining a clean fuel system is regularly replacing the fuel filters. We recommend OEM Motorcraft filters. As with the above recommendation this won’t guarantee that your CP4 doesn’t fail, but if you regularly change the filters, the chance of contaminants entering the fuel system is much lower.

The Motorcraft FD4615 Replacement Fuel/Water Separator Filter is a genuine OEM replacement filter for your 2011-2016 6.7L F-Series Ford. This is the same filter that came on your truck from factory and is guaranteed by Ford's factory warranty.

Motorcraft

2017-2023 Powerstroke OEM Motorcraft Fuel/Water Separator Filters (FD4647)

Motorcraft

2011-2016 Powerstroke OEM Motorcraft Fuel/Water Separator Filters (FD4615)

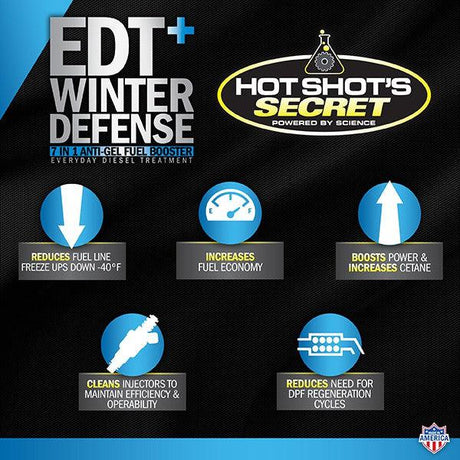

5. Run fuel additives

Our final recommendation is adding a diesel fuel additive everytime you fill up the tank. A quality additive can help restore the lubricity to ultra low sulfur diesel and reduce friction by coating the internal parts of the fuel system. While this won’t guarantee that your pump won’t fail, it can be beneficial.

Hot Shot's Secret Everyday Diesel Treatment is your go-to solution to keep your truck running smoothly and well down the road. Designed for all Diesel engines being ashless and having no adverse effects on engine components means you can use this worry-free! Maintaining injectors, increasing fuel economy and lubricity and stabilizing fuel are all benefits you can expect from the Everyday Treatment.

Hot Shot's Secret

Hot Shot's Secret Everyday Diesel Treatment (HSSEDT04)

Hot Shot's Secret

Hot Shot's EDT+ Winter Defense (EDTWAG)

In case of Failure

In the worst case scenario, if your CP4 does fail and your pockets are about to be significantly lighter due to the need to rebuild your fuel system, we’ve included some recommended kits below. It is highly recommended that once you do replace your fuel system, you either install a CP4 Bypass disaster prevention kit and an Exergy Fuel System Saver (listed above) or a DCR conversion kit.

Industrial Injection

2011-2014 Powerstroke Disaster Kit (3GG101)

Industrial Injection

2014-2016 Powerstroke C&C Disaster Kit (3GE103)

Industrial Injection

2020+ Powerstroke Disaster Kit (3GH101)

Conclusion

Though instances of CP4s failing aren’t excessively common, we have seen it happen and when it does it’s not pretty. There are many options out there that can lessen your chances of CP4 failure including: making sure you regularly change your fuel filter, ensuring you are using the proper fuel from a reputable source, using fuel additives to restore fuel lubricity, using upgraded filters, and using a bypass kit, but if you want to ensure you don’t risk failure of your fuel system, we recommend the DCR pump conversion.