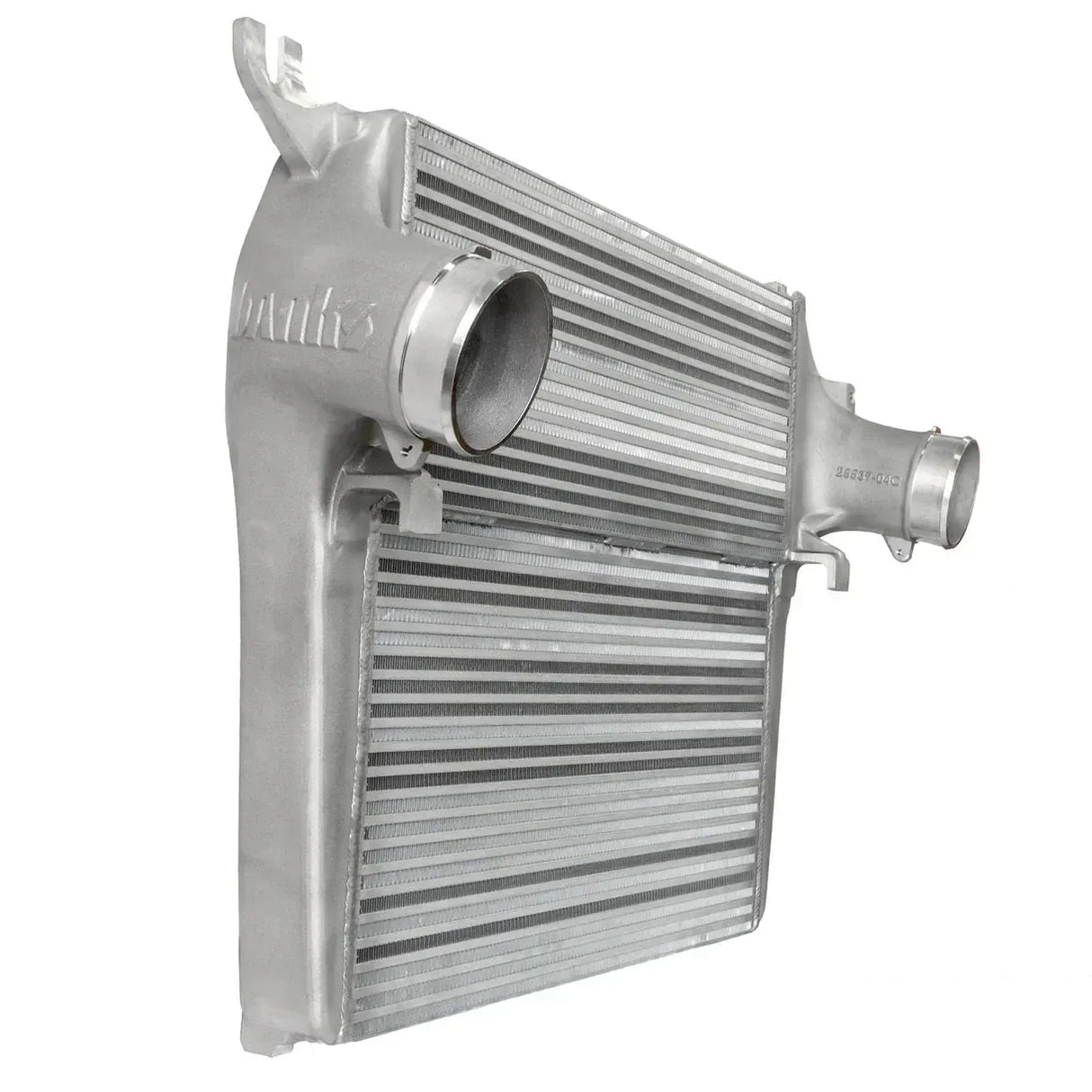

2010-2012 Cummins Intercooler Upgrade (25986)

Purchase to earn 3037 Dirty Dollars Learn More

Description

Description

Fits

|

Year |

Make |

Model |

| 2010-2012 | Dodge/Ram | 2500/3500 w/ 6.7L Cummins |

The Banks Technicooler for 2010–2012 RAM 6.7L trucks is built to fix what the stock intercooler can’t: cooling under pressure. It is designed to outflow and outcool, so it keeps intake temps down and power up, especially when towing or hauling in the heat. With better throttle response, lower EGTs, and more consistent performance, it lets your RAM pull harder, longer.

Part Number: 25986

Features

Features

- Maintain full power even when things heat up

- Delivers consistent performance under extreme temps

- Lowers EGTs for better efficiency and reliability

- Boosts power, durability, and fuel mileage

- Packs more dense air into your cylinders

- Massive 4" inlet and outlet with patent-pending design

- 78% more flow area compared to stock

- Over twice the core volume of factory intercoolers

- Durable cast aluminum end tanks built for efficiency

- Upgraded boost tubes cut down pressure loss

- Built to handle 1,000+ horsepower setups

- Comes with everything needed for install

Additional Info

Additional Info

Banks massive intercooler upgrade for the 2010-2012 Cummins 6.7L uses a 3.25" thick core that is over twice as thick as the factory charge air cooler.

With an overall core volume of 2401.4 cubic inches, that's more than any competitive product tested including Mishimoto, Wagner, and AFE, and over 2x the volume of the stock unit.

The cast aluminum end takes (manifolds) with massive 4" inlets and outlets feature 30% more mass flow than competitive 3.5" end tanks, and a whopping 78% larger flow area than the stock charge air cooler.

All this results in lower intake temperatures under sustained load with over 4.3x less boost pressure loss across the system.

Mass Air Flow Chart

Pressure Drop Chart

Dual-Thickness Core

A well-engineered intercooler must perform a difficult balancing act between effectiveness and efficiency while allowing air to flow through it to cool the radiator and engine. It must cool the charge air better than stock (effectiveness) while maintaining boost pressure (efficiency). This is often easier said than done.

Increasing core thickness improves heat rejection but it can also result in a loss of boost pressure. Make it too thick, and it can prevent air from passing through and cooling the engine. Uneven distribution of airflow across the core can result in unwanted hot and cold zones. Combining two cores of different thickness solved this challenge. And for those with compound turbos, the core is pressure tested to withstand 1,000+ horsepower applications.

Elliptical Inlet and Outlet

We wanted to increase the diameter of the inlet and outlet but there there was so little space between the radiator core-support and frame that enlarging them to 4" in diameter simply wasn't possible without cutting the factory core support. The solution took months to perfect.

We engineered an elliptical inlet and outlet using NACA (known today as NASA) technology. The transition from elliptical to round is handled by custom 5-ply silicone couplers. This results in lower intake air temperatures under sustained load with over 4.3x less boost pressure loss across the system. In other words, better sustained power when you need it the most.

Real World Testing

Real World Testing

Engineering Features

Engineering Features

Questions and Answers

Questions and Answers

Have a Question?

Be the first to ask a question about this.